We love

our products.

One of the greatest pleasures in life is to have the opportunity to work daily with something that offers such satisfaction. We love what we do, what we create, what we deliver to our customers; those are not just sentiments, it is the passion we share which underpins everything we do, and the more we put into our work, the greater the sense of achievement.

Our mission is to combine the complexity of a scent and a flavour. Our talent is knowing how to do that. Our unswerving goal is to get it right, quickly, and consistently.

Over 30 years of experience in this sector has allowed FlavourArt to carve out a key role among specialized producers.

Constant investments in Research and Development, innovative machinery, and continuous training enable us to tackle complex and articulated projects within defined time scales, and to produce outstanding results.

FlavourArt can internally boast the best and most advanced technologies. We utilize Gas Chromatography / Spectrophotometry, both Linear and Bi-dimensional, Double Column Gas Chromatography with Flame Ionization, High Performance Liquid Chromatography (HPLC), Solid Phase Micro Extraction (SPME), Viscosimetry, and Flash Point, as well as a structured series of repetitive analyses to ensure exceptionally high levels of quality control.

The cutting-edge

technology

at our service.

The production technology is simple, i.e., combining different substances together until the desired result is achieved. We know what we must compose but doing so manually is a repetitive and unsatisfactory activity, so we have long believed that in this area of manufacture, machines are better suited than humans.

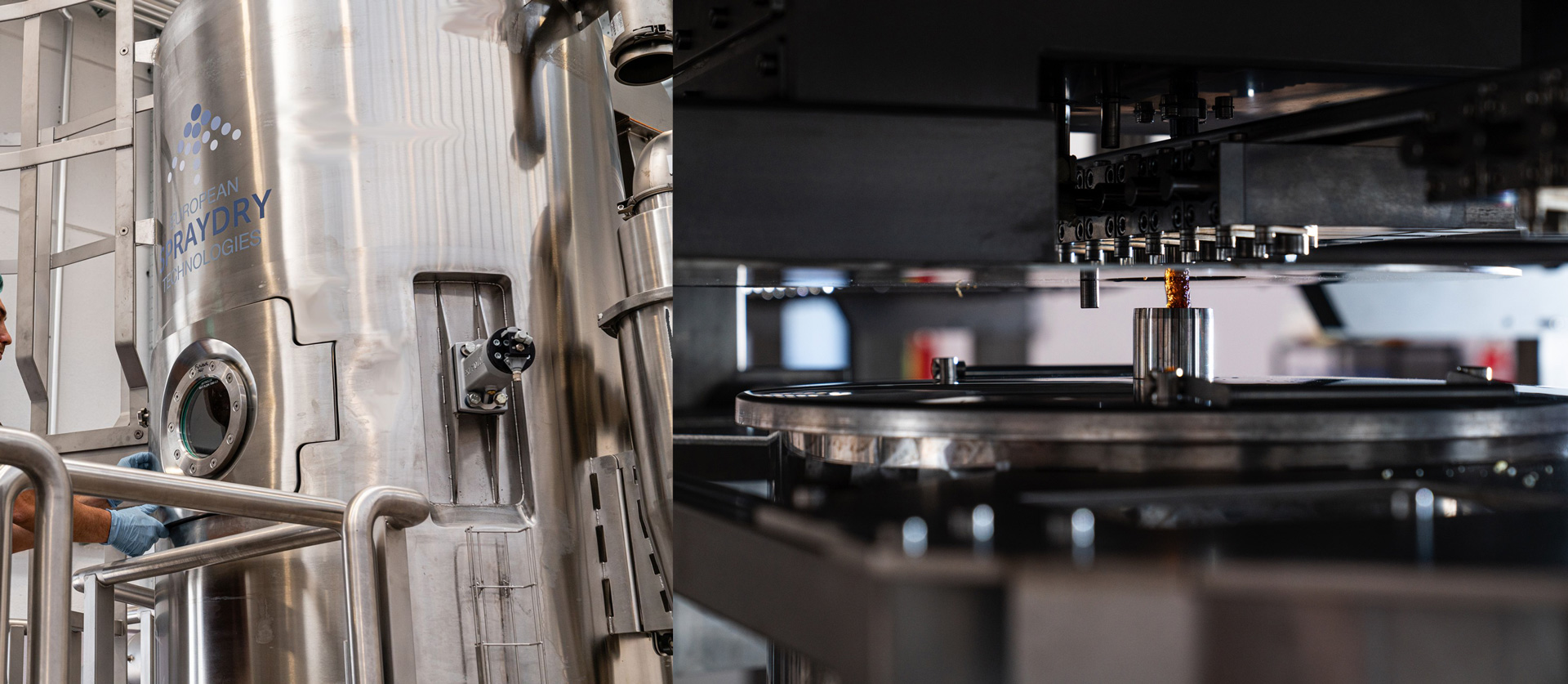

Over the years, FlavourArt has invested heavily in the best robotic technology. In 2013, we welcomed Roxane A, our first robot mixologist. Ultra-dependable and tireless, she has followed and helped us step by step, her heart never missing a single beat.

In 2022, coinciding with the construction of our new factory extension, we once again welcomed a most talented lady from across the Alps.

Roxane GT is the latest incarnation of Roxane A, which for FlavourArt represents a significant, technological leap in production, and the potential to increase production capacity by one hundred times. These two sisters work in perfect harmony, and we are confident that they will continue to deliver perfect formulations.

2022 is a year of further innovations for FlavourArt, introducing the ability to produce powder flavours using Spray Dry technology.

![]()

ClearStream Onward

February 2015 marked the beginning of a new and important scientific venture between FlavourArt and TRUSTiCERT, a spinoff of the University of Milano Bicocca which has been operating since 2010 and which has been successful in the sharing of technological expertise from the academy with numerous companies by mutual collaboration.

The management of FlavourArt and TRUSTiCERT signed a significant agreement aiming to bring both the scientific expertise and the most advanced equipment from the University to the emerging e-cigarette industry.

The full integration and implementation of the project will inevitably be a long-term process involving continuous efforts and commitments from both parties to achieve the ambitious goals visualized by Massimiliano Mancini, CEO of FlavourArt.

The full integration and implementation of the project will inevitably be a long-term process involving continuous efforts and commitments from both parties to achieve the ambitious goals visualized by Massimiliano Mancini, CEO of FlavourArt. TRUSTiCERT will put a scientific seal on FlavourArt products and, at the end of the project, several far-reaching objectives will have been achieved; these include, among others, endorsement of the purity of e-liquids and their ingredients, the accurate assessment of both the levels and types of emissions produced by e-cigarettes, and confirmation of the absence of heavy metals and harmful compounds from the vaporization process.

The initiative will certainly be of great benefit to all e-cigarette users, who will be regularly informed of the ongoing progress via the online portal, “ClearStream ONWARD”. This will be a useful tool for communicating analysis results, imparting new knowledge developed through the research, and for offering an insight into the laboratory operations. The dedicated web portal will be easy to navigate and friendly in both language and graphical interface; not least, inquiring minds will have the opportunity for in-depth exploration into technical aspects on a dedicated section on the website.